Expansion joints in concrete construction are essential for managing the natural expansion and contraction caused by temperature fluctuations. They are key to maintaining the structural integrity and longevity of a concrete slab. In this guide, we’ll dissect the role of expansion joints, illustrate their importance, and provide practical know-how on installation and upkeep, tailored to anyone looking to understand or work with concrete.

Key Takeaways

Expansion joints are critical in concrete construction to allow for movement caused by temperature changes and shrinkage, preventing cracks and structural damage.

Different types of expansion joints, such as isolation, construction, and contraction joints, serve various purposes and require specific materials and placement strategies for effective function.

Regular maintenance and correct repair techniques for expansion joints are essential to sustain the integrity and functionality of concrete structures, with considerations for aesthetics in decorative concrete applications.

The Importance of Expansion Joints in Concrete

Expansion joints, also known as control joints, are intentionally incorporated into concrete structures to facilitate movement without compromising structural integrity. They are strategically placed when concrete is laid around structures or objects, with cuts for joints made within 12 hours after pouring to prevent uncontrolled cracking. What makes them so essential?

In the absence of proper expansion joints, concrete structures may suffer from weakened integrity due to stress points caused by movement. Imagine the stress a concrete slab experiences due to temperature changes. Without a place to expand or contract, the slab could develop significant cracks, threatening the safety and longevity of the structure.

Temperature Changes and Shrinkage Movement

The role of expansion joints is fundamentally linked to the effects of temperature changes and shrinkage movement on concrete. Concrete, like any material, expands and contracts in response to temperature fluctuations. As the mercury rises, concrete expands, and as it falls, it contracts. Without adequate expansion joints, concrete can suffer damage from tension against inflexible materials, as it lacks the necessary space to accommodate these dimensional changes.

Moreover, concrete experiences shrinkage movement after it has hardened. This shrinkage can contribute to tensile pressure and crack formation. Without expansion joints to absorb this pressure, your immaculate concrete slab could soon resemble a spider’s web of unsightly cracks.

Preventing Cracks and Water Infiltration

Beyond managing movement, expansion joints play a critical role in preventing cracks and water infiltration. They maintain the surface integrity of concrete, allowing for movement beneath the surface, which mitigates the development of cracks and keeps them superficial.

The prevention of cracks is only the beginning, considering the potential consequences of their formation. Without proper sealing, water can seep into these cracks. This is especially critical for joints exposed to outdoor conditions, where water infiltration can cause severe structural damage.

Even decorative concrete flatwork requires expansion joints to prevent unsightly cracking, ensuring longevity without compromising the overall aesthetic.

Types of Expansion Joints in Concrete

Just like every concrete structure has its own unique characteristics, the expansion joints required to sustain them also vary. Various types of expansion joints, namely isolation joint, construction, and contraction joints, serve different purposes in concrete structures.

Isolation joints are used to separate one concrete slab from adjacent structures to accommodate movement, while construction joints come into play where two consecutive placements of concrete meet and can also serve as contraction joints to regulate cracking.

Then we have contraction joints, also known as control joints, which preemptively create weakened planes in the concrete to control and localize cracking due to shrinkage.

Material-Based Expansion Joints

In the realm of expansion joints, the selection of material holds significant importance. From foam, rubber, and cork to fiberboard, silicone, and vinyl – each material offers unique benefits and properties.

Consider the following options for different purposes:

Fiberboard: Its flexibility accommodates concrete movement and prevents cracking.

Silicone filler: Celebrated for its flexibility, durability, and resistance to mold and mildew.

Bitumen-impregnated fiberboard or closed-cell polyethylene like FillPro Flat Backer Rod: For moisture resistance.

Location-Specific Expansion Joints

Location matters! Expansion joints should be strategically placed where a concrete slab encounters another structural element, such as where it meets a building, another slab, or external features like a pool deck.

For a real-world example, consider the Dodmoor Bridge A45, which employs wing-wall joints. Or take a look at the Bretton Lane Bridge over the A55 in North Wales, where road-spanning expansion joints accommodate movement specific to their structures. These location-specific expansion joints are tailored for different movement dynamics and physical features of the transportation infrastructure, ensuring the safety and longevity of the structures, all while maintaining a straight line.

Installation of Expansion Joints in Concrete

The correct installation of expansion joints can be compared to preparing a stage for a theatrical performance. It involves considering spacing, depth, and joint materials to ensure effective movement accommodation.

The spacing of joints should consider the aspect ratio of the slab, with an ideal ratio being 1:1 and not exceeding 1.5 to maintain effectiveness. The depth of the expansion joints must also be considered. For effectiveness, the joint should extend the full depth and width of the slab, with the contraction joint depth being at least a quarter of the thickness of the slab.

Proper Spacing and Depth

How far apart should expansion joints on slabs be? Ideally, joints should be positioned approximately 30 times the slab thickness apart to adequately accommodate movement. Also, control joints should be cut to a depth of 25% of the slab thickness, meaning each control joint on a 4-inch thick slab should have 1-inch deep joints.

In hot weather, joints between concrete slabs should be cut within 6-12 hours after finishing concrete to prevent uncontrolled cracking. For example, a 4-inch slab should have joints spaced 8-12 feet apart, and these joints can be strategically placed under walls or carpet areas to minimize visibility.

Joint Materials and Preparation

The choice of joint materials and preparation for their installation is crucial for the overall success of the expansion joint installation. Materials commonly used for concrete expansion joints include:

Asphalt-saturated fiber

Cork

Sponge rubber

Closed-cell foam fillers like polyethylene and polypropylene

Before installing expansion joint materials, the concrete surfaces need to be clean and dry to ensure proper adhesion of the joint to any sealant used. A foam backer rod is often inserted into the cleaned joint to provide a base for the new sealant and control its depth. The precise cutting of the joint to the recommended width and depth is crucial in the proper installation of expansion joints.

Maintenance and Repair of Expansion Joints

Sustaining the lifespan of expansion joints hinges on regular maintenance and timely repair. Regular maintenance of expansion joints is crucial for the longevity and functionality of concrete structures. A tailored maintenance checklist can help in keeping a regular schedule for checking and maintaining expansion joints.

Indicators for maintenance can include visible signs of wear, material degradation, or a decrease in joint performance. Repair works for expansion joints may involve cleaning the joint, removing old sealant or filler, and installing new materials to restore joint function.

Regular Inspections

Conducting regular inspections is like performing regular health check-ups on the joints. An installation and ongoing use checklist is a crucial tool for ensuring that expansion joints are installed correctly and consistently perform well during their service life.

During these inspections, things to look for include:

Any signs of damage to the expansion joints

Ensuring that all anchors, guides, and supports remain secure and in good condition

Ensuring that expansion joints are unobstructed and able to move freely to prevent movement restriction, which can lead to the failure of the joint system.

Repair Techniques

As for the repair of expansion joints, it is vital to follow these steps:

Remove old sealant materials.

Meticulously clean the joint before applying new repair materials.

Use polyurethane sealants or materials like Belzona 4111 (Magma-Quartz) due to their high movement capability and elastic recovery.

The repair materials must be compatible with existing concrete and capable of handling the expected range of movement. After the repair, a surface coating like Belzona 5231 can be applied over the repaired area for protection and aesthetics.

Expansion Joints in Decorative Concrete

Expansion joints in decorative concrete serve more than just a functional purpose; they are also key to maintaining the flawless aesthetic of the design. Cracking in stamped decorative concrete, for instance, is controlled by cutting along the pattern design, which also helps to make the joints inconspicuous.

To maintain the integrity of stamped patterns, decorative concrete joints require precise planning and execution. The joints should penetrate only a quarter of the slab’s depth, ensuring the structural stability without disrupting the intricate design.

Aesthetic Considerations

In the realm of decorative concrete construction, visual appeal is as significant as practicality. Expansion joints can be made less visible by using materials that color-match the concrete. This allows for a seamless finish, ensuring the expansion joint does not disrupt the visual appeal of the design.

In stamped concrete, contraction joints can be artfully integrated into the pattern and design to enhance the overall aesthetic while ensuring functionality. Choosing the right sealants is also crucial to ensure they do not negatively affect the look of the stamped pattern or colors.

Special Installation Techniques

The installation of expansion joints in decorative concrete demands unique techniques. For instance, joints can be saw-cut into the concrete, helping maintain the visual appeal of decorative concrete while still providing necessary joint functionality.

This delicate balance between aesthetics and functionality underscores the importance of proper planning and execution in the installation of expansion joints in decorative concrete. The end goal is to ensure that the expansion joints do their job without disrupting the beauty of the decorative concrete design.

Case Studies: Expansion Joints in Action

Real-world examples can provide the best understanding of the significance of expansion joints. Here are some examples of where expansion joints are used:

Roads and bridges

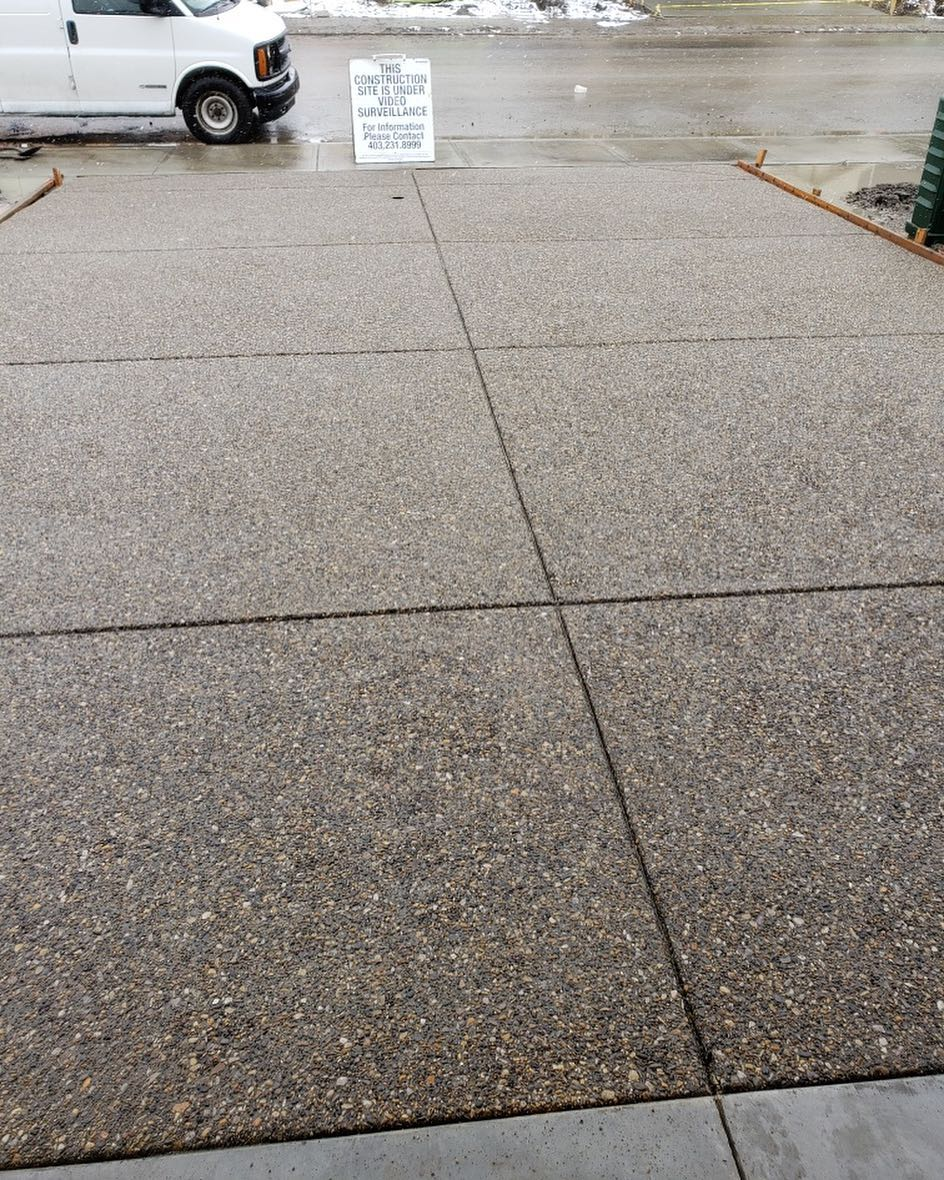

Driveways

Pool decks

Sidewalks

Expansion joints, with their varying joint depth, are integral in handling the transfer flexural stresses produced by temperature fluctuations and physical loads, ensuring effective load transfer.

Commercial Buildings

Commercial buildings, with their large-scale designs and heavy traffic, require a well-planned system of expansion joints for structural integrity. Take the Manchester Airport’s Terminal-2 car park or Hartsfield Jackson Airport’s Rental Car Parking Facility as examples. These structures incorporate expansion joints to accommodate the movement specific to their structure, ensuring sustainable, durable, and functional designs.

Residential Construction

The importance of expansion joints extends to residential construction as well. These joints accommodate movement, prevent cracking, and ensure the longevity of the structure, making them a non-negotiable feature in any concrete construction project.

Summary

From building the towering skyscrapers of the cityscape to the humble driveway of a suburban home, expansion joints play a pivotal role in ensuring the longevity and integrity of concrete structures. Whether it’s managing temperature-induced expansion and contraction, preventing unsightly cracks, or maintaining the aesthetic appeal of decorative concrete, these seemingly insignificant gaps in concrete hold the key to durable and sustainable construction.

Frequently Asked Questions

What are the rules for expansion joints in concrete?

Expansion joints in concrete should be no farther apart than 2 to 3 times the total width of the concrete in feet. For a 4-inch thick concrete slab, expansion joints should be no more than 8 to 12 feet apart.

When should you use expansion joints in concrete?

Expansion joints should be used in concrete to allow the slab to move without putting stress on surrounding structures. They are typically placed where a slab meets a building, where a front slab edge meets another slab, and where a pool deck meets the coping.

How far apart are expansion joints in concrete?

Expansion joints in concrete should be no farther apart than 2 to 3 times the total width of the concrete in feet. This spacing helps to control cracking and movement.

What happens if you don’t put expansion joints in concrete?

Without expansion joints in concrete, there is a risk of significant cracks forming due to the stress caused by normal movement from temperature changes and moisture conditions.

What are the joints in concrete called?

The three types most common type of joints used in concrete are called isolation joints, construction joints, and contraction joints, which can also function as expansion and control joints, respectively.

Concrete vs Pavers: A Complete Comparison Concrete and pavers each...

Expansion joints in concrete construction are essential for managing the...

Are you aiming to protect and prolong the life of...

Understanding the intricacies of concrete drying is crucial for both...